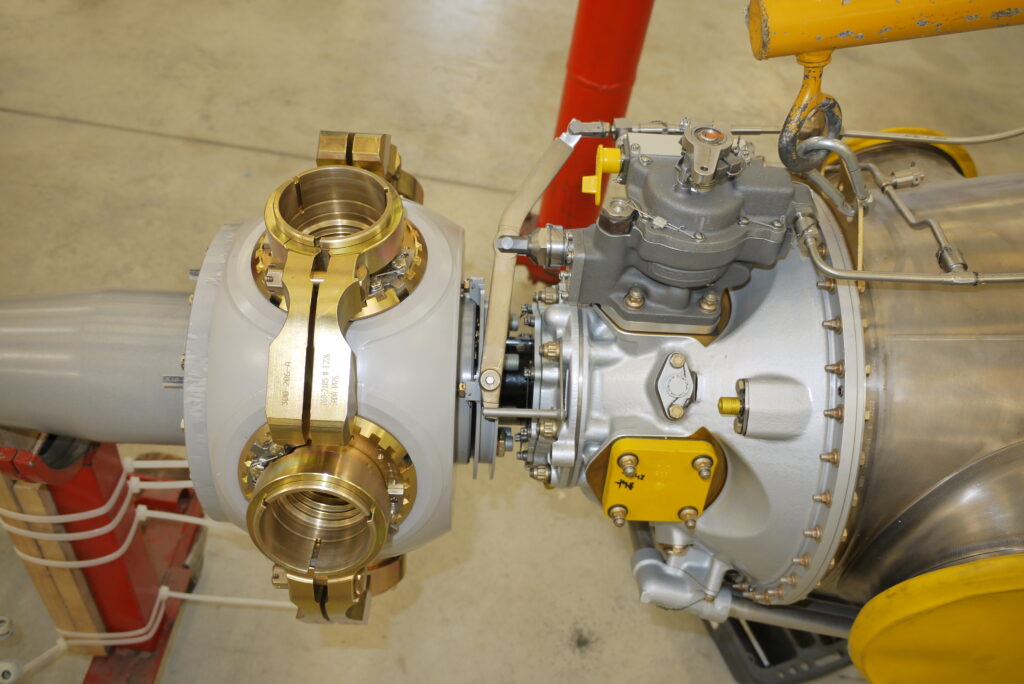

AEROSERVIS Design Department is currently working on most complex project in its history: replacement of M601E engines on L 410 UVP-E and L 410 UVP-E20 by Pratt&Whitney Canada PT6A-42 engine This is not first time, when PT6 engine is associated with the L 410 aircraft. In late sixties, when L 410 was developed and certified, the prototypes were powered by PT6A-27 engines, as well as first 38 serial production aircraft L 410A manufactured in early seventies. The Pratt&Whitney Canada PT6 series engine is most famous and frequent example of small turboprop engine around the world, having excellent reputation in reliability, power, flexibility and operational support. In 2013 Pratt&Whitney Canada celebrated 50th anniversary of delivery the first PT6. Because M601 engine was developed as direct replacement of PT6, while AEROSERVIS started to evaluate possible replacement, the PT6 was logical choice. There were several reasons to take decision to launch such a complex and expensive project. After taking-over the former Walter Engines by GE and forming GEAC, all costs related to operation of M601 engines start rising, customer approach by GEAC is not satisfactory, there still persist reliability issues from Walter times, while new appear (outer liner locks and related mandatory boroscopy, fuel control unit issues…). Compared to M601, the PT6 offers higher TBO, more flexible maintenance program, well developed maintenance and spare parts support worldwide. The whole installation of new engine comprises:

- PT6-42 engine (flat-rated to 800 HP, i.e. max. contingency power of current M601E engine)

- New all-aluminium five blade propeller Avia AV-725

- 300 Amps starter-generator (compared to original 200 Amps one) giving more electrical power available for next possible appliances installed (for example air-condition)

- Replacement of several aircraft components

The installation is designed so to modify as much as possible existing components of original M601 equipped aircraft to save costs of installation. The main benefits are:

- Higher engine TBO: basic 3600 FH with possibility of individual TBO escalation, no cyclic and calendar TBO limits, and thus lower maintenance reserves for power plant

- Lower fuel consumption

- Increased cruise speed close to existing Vmo

- Less aircraft noise both inside and outside due to lower prop RPM in both take-off and cruise

- Improved “hot and high” performance

- Because several original aircraft components with TBO/SL limits are replaced by new ones with no TBO/SL limit, simplifying the maintenance and lowering maintenance costs.